Quality control is a critical factor in any successful supply chain management operation. It is essential to ensure that customers receive the best quality products and services in a timely manner. Without quality control, the efficiency and success of the supply chain could suffer. To ensure the highest level of quality, it’s important to have the right tools, processes, and best practices in place. This guide provides expert advice on how to set up and maintain a quality control system in your supply chain management operations.

Factors Affecting Quality in Supply Chains

When it comes to supply chains, there are several factors that can have a significant impact on the quality of products and services.

- One of the main factors is the reliability and consistency of suppliers. If suppliers are unable to deliver materials or components on time or if they consistently provide subpar quality, it can lead to delays and defects in the final products.

- Another factor is the efficiency of production processes. If there are bottlenecks or inefficiencies in the manufacturing or assembly processes, it can result in errors, defects, and lower quality products. It’s crucial to regularly evaluate and optimize these processes to ensure they are running smoothly and producing the desired level of quality.

- Furthermore, communication plays a crucial role in maintaining quality in supply chains. Effective communication between different stakeholders, such as suppliers, manufacturers, and distributors, is essential to ensure that everyone understands the quality standards and requirements. Miscommunication can lead to misunderstandings and deviations from the desired quality level.

- Supply chain disruptions, such as natural disasters or unexpected events, can also impact the quality of products and services. These disruptions can lead to delays, shortages, or changes in suppliers, which can affect the overall quality of the final products.

- Employee training and competence are factors that significantly affect quality in supply chains. Employees need to be properly trained on quality control procedures, equipment usage, and industry best practices. A lack of training or incompetence can result in errors, defects, and overall lower quality products and services.

Best Practices for Ensuring Quality in Supply Chains

Ensuring quality in supply chains is a complex task that requires the implementation of best practices. Here are some key strategies to consider when aiming for excellence in your supply chain management operations.

- First and foremost, it is essential to establish clear quality standards and communicate them effectively to all stakeholders involved in the supply chain. This includes suppliers, manufacturers, distributors, and employees. By setting clear expectations, everyone understands their role in maintaining quality and can work towards achieving it.

- Regular monitoring and evaluation of processes and performance are crucial. This involves conducting audits, inspections, and quality control checks at various stages of the supply chain. By identifying any deviations or potential issues early on, corrective actions can be taken to prevent further problems and maintain quality standards.

- Investing in employee training and development is another important best practice. Ensuring that all individuals involved in the supply chain are knowledgeable about quality control procedures and best practices will minimize errors and enhance the overall quality of products and services.

- Collaboration and cooperation among stakeholders is also key. By fostering a culture of teamwork and open communication, everyone can work together towards achieving the common goal of maintaining high-quality standards. Sharing information and best practices can also lead to continuous improvement and innovation in the supply chain.

- Finally, embracing technology and automation can significantly improve quality control in supply chains. Utilizing tools and software for data analysis, tracking, and reporting can provide valuable insights into potential quality issues and help in making informed decisions.

Implementing Effective Quality Control Measures

Implementing effective measures while doing quality control in Vietnam is crucial for maintaining high standards of quality in supply chain management. To ensure the success of these measures, it is important to have a systematic and well-planned approach.

One of the first steps is to establish a robust quality control framework. This involves defining key quality control parameters, such as product specifications, performance criteria, and inspection procedures. It is important to involve all relevant stakeholders in the development of these parameters to ensure their buy-in and commitment.

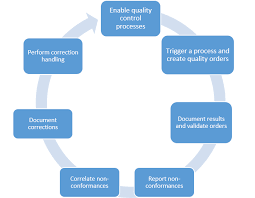

Next, it is important to establish a clear process for monitoring and evaluating quality control measures. This includes setting up regular inspections, audits, and reviews to assess the effectiveness of the implemented measures. By conducting these assessments on a regular basis, any deviations or non-compliance can be identified and addressed promptly.

Implementing technology and automation can greatly enhance the effectiveness of quality control measures. Utilizing software and tools for data collection, analysis, and reporting can streamline the process and provide real-time insights into quality issues. This enables quick decision-making and corrective actions.

Additionally, effective training and education programs for employees are essential. This includes training them on quality control procedures, using quality control equipment, and understanding industry best practices. By investing in employee development, you can ensure that they are equipped with the necessary skills and knowledge to effectively implement quality control measures.

Lastly, it is important to foster a culture of continuous improvement. Encouraging feedback and suggestions from employees and stakeholders can lead to innovative solutions and better quality control measures. By regularly reviewing and updating the quality control framework, you can adapt to changing market trends and customer expectations.

Benefits of Maintaining High Standards of Quality in Supply Chain Management

Ensuring high standards of quality in supply chain management comes with a wide range of benefits for businesses. Maintaining a focus on quality control throughout the supply chain can lead to increased customer satisfaction, improved operational efficiency, and a competitive advantage in the market.

- First and foremost, maintaining high standards of quality in supply chain management leads to greater customer satisfaction. When customers receive products and services that consistently meet or exceed their expectations, they are more likely to remain loyal to the brand and become repeat customers. Satisfied customers also tend to spread positive word-of-mouth, which can attract new customers and contribute to business growth.

- Moreover, a focus on quality control can enhance operational efficiency. By implementing effective quality control measures, businesses can minimize errors, defects, and rework, resulting in a streamlined supply chain process. This leads to improved productivity, reduced costs, and faster turnaround times, ultimately boosting overall operational efficiency.

- Additionally, maintaining high standards of quality can provide a competitive advantage in the market. Businesses that prioritize quality control differentiate themselves from competitors and establish a reputation for delivering superior products and services. This can help attract new customers, retain existing ones, and ultimately gain a larger market share.

Conclusion

In conclusion, implementing effective quality control measures in supply chain management is crucial for businesses to ensure the highest level of quality in their products and services. By addressing factors such as supplier reliability, production process efficiency, communication, supply chain disruptions, and employee training, businesses can proactively maintain and improve quality standards throughout their supply chains.

By following best practices such as establishing clear quality standards, regularly monitoring and evaluating processes, investing in employee training, fostering collaboration among stakeholders, and embracing technology and automation, businesses can achieve excellence in quality control. Real-life examples from leading companies in various industries demonstrate the effectiveness of these practices and the benefits they bring.

Maintaining high standards of quality in supply chain management leads to increased customer satisfaction, improved operational efficiency, and a competitive advantage in the market. Customers who receive high-quality products and services are more likely to remain loyal and spread positive word-of-mouth, contributing to business growth. Moreover, a focus on quality control enhances operational efficiency by minimizing errors and rework, resulting in cost savings and faster turnaround times. Lastly, businesses that prioritize quality control differentiate themselves and establish a reputation for excellence, attracting and retaining customers while gaining a larger market share.

In conclusion, by implementing effective quality control measures, such as conducting factory audits, businesses can reap the benefits of improved customer satisfaction, enhanced operational efficiency, and a competitive edge in the market.